A “Champion Crofts Gears product”. Crofts Gears is renowned for our tough and industry ready worm gear range. Over the years we have perfected worm tooth form to provide maximum torque capacity and optimum efficiency. Worm gear units are extremely versatile and used in abundance across a large variety of applications, especially where large gear reductions are required.

Smooth and quiet operation.

Up to 8 multi-start worms for high-speed applications.

High torque applications.

Hardened and ground worm profile for effective meshing.

Universal, W Range and TW Series:

Tried and trusted “workhorse”. From small universal units to heavy-duty worm gear units for arduous applications. Single reduction units available from 5:1 to 70:1 and double reduction with ratios up to 4900:1. Available in a wide range of mounting and motorised variants.

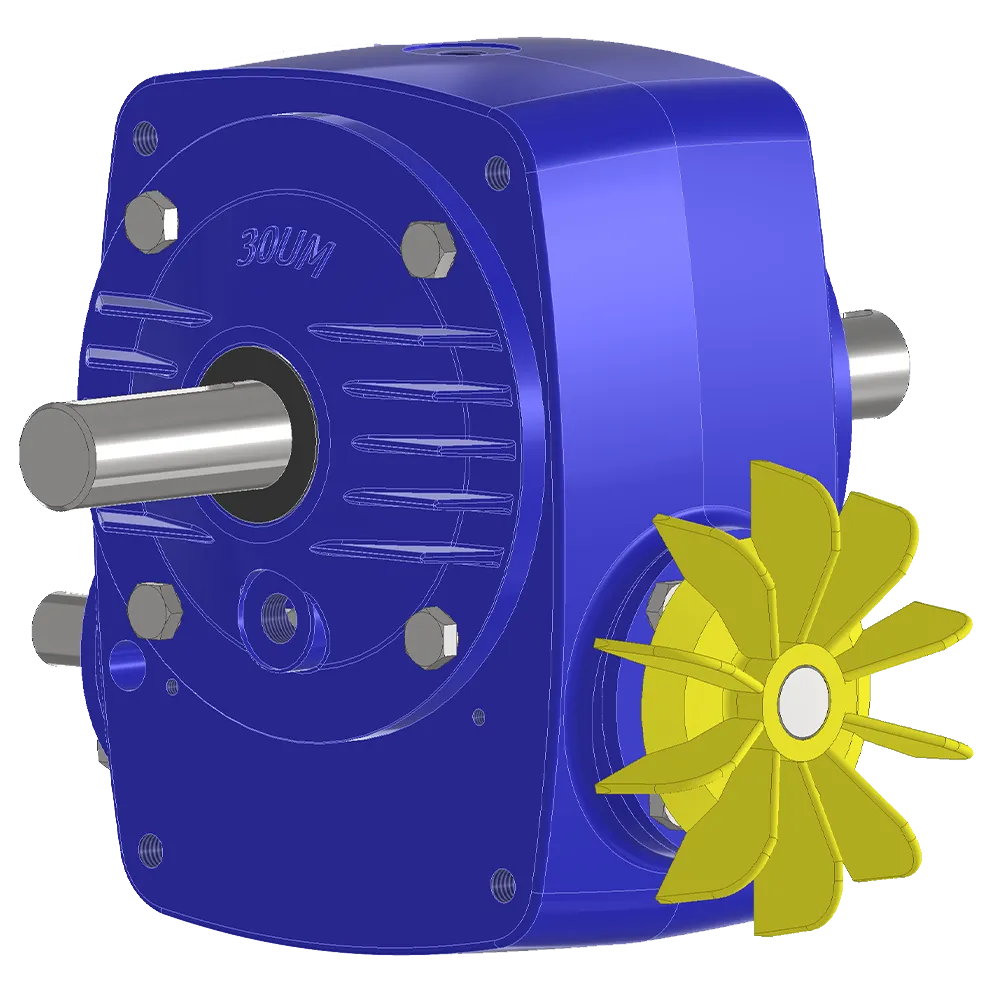

The Universal range or UUs are the smallest of our offering. Available in 4 sizes – sizes 17 to 35. Highly robust compact worm gearbox in cast iron cases.

The W range is available in 6 sizes – sizes 40 to 90 with a broad spectrum of configurations. The W range are widely used and easy to maintain.

The Crofts Gears Titan series is heavy duty worm gearbox for the most arduous of applications. Its compact and rigid design is particularly advantageous for slow-moving machinery, offering a broad range of gear ratios from 75:1 to 4900:1 and available in 7 sizes – sizes 10 to 24. These units excel in high torque, low-speed applications and conform to BS-721 standards, ensuring flexibility in mounting options. The dual-stage reduction provides enhanced torque multiplication and efficiency, significantly improving the overall performance of heavy-duty applications.

Typical applications:

• Conveyor drives, mills, crushers etc.

• Agitators and mixers in mining, cement, chemical, wastewater and effluent industries.

• Cooling towers and rotating tables etc.

© Crofts Gears 2024 | All Rights Reserved | Crofts Gears Australia Pty Ltd ( ABN 54 677 013 857) | Developed & Designed by FJ worX